Discover the durable and weather-resistant Suntuf panels‚ ideal for various projects like greenhouses and pergolas. This guide offers a comprehensive overview of tools‚ best practices‚ and step-by-step instructions for a successful installation process.

What is Suntuf?

Suntuf is a high-quality corrugated polycarbonate roofing material designed for durability and weather resistance. It is widely used for greenhouses‚ pergolas‚ and other outdoor structures due to its lightweight and UV-protective properties. Suntuf panels are known for their strength and ability to withstand harsh weather conditions‚ making them a popular choice for both residential and commercial projects. The material is easy to cut and install‚ offering a cost-effective solution for roofing needs. Its translucent nature allows natural light to filter through while providing protection from the elements; Suntuf is a versatile and reliable option for anyone looking to enhance their outdoor spaces with a durable and visually appealing roofing solution.

Why Choose Suntuf for Your Project?

Opt for Suntuf due to its exceptional durability‚ weather resistance‚ and lightweight design‚ making it ideal for outdoor projects like greenhouses and pergolas. Its UV protection ensures longevity‚ while its translucent nature allows ample natural light. Easy to cut and install‚ Suntuf offers a cost-effective solution. It withstands harsh weather conditions‚ including heavy rain and extreme temperatures‚ ensuring your structure remains secure. Additionally‚ Suntuf requires minimal maintenance‚ keeping your project looking great for years. Its versatility and reliability make it a top choice for enhancing outdoor spaces with a durable and visually appealing roofing solution. Choose Suntuf for a hassle-free and long-lasting roofing option that meets your project needs effectively.

Preparing the Site for Installation

Ensure the area is clear of debris and obstructions. Verify the structure is level and secure. Check for any sharp edges or protrusions that could damage the panels.

Assessing the Structure for Suntuf Panels

Evaluate the structural integrity and ensure it is level and secure. Check for any damage‚ rot‚ or uneven surfaces that could affect panel installation. Measure the width of the structure to determine the number of panels needed‚ ensuring proper spacing and alignment. Verify that the frame can support the weight of the Suntuf panels‚ especially in areas with heavy wind or snow. Inspect for any sharp edges or protrusions that may damage the panels. Ensure the structure is compatible with Suntuf’s corrugated design and that all necessary measurements align with the panels’ dimensions. This step is crucial for a smooth and successful installation process.

Clearing the Area and Preparing the Surface

Before installation‚ clear the area of debris‚ vegetation‚ and obstructions. Ensure the surface is clean‚ dry‚ and free from sharp objects. Inspect for any cracks or unevenness and address them to prevent damage to the panels. Remove existing roofing or coverings‚ if applicable‚ and ensure the frame is secure. Use a broom or pressure washer to clean the surface thoroughly‚ promoting better adhesion and sealing. Avoid direct sunlight exposure to prevent panel warping during installation. Proper preparation ensures a stable and even base for Suntuf panels‚ enhancing durability and weather resistance. This step is vital for achieving a professional-grade installation.

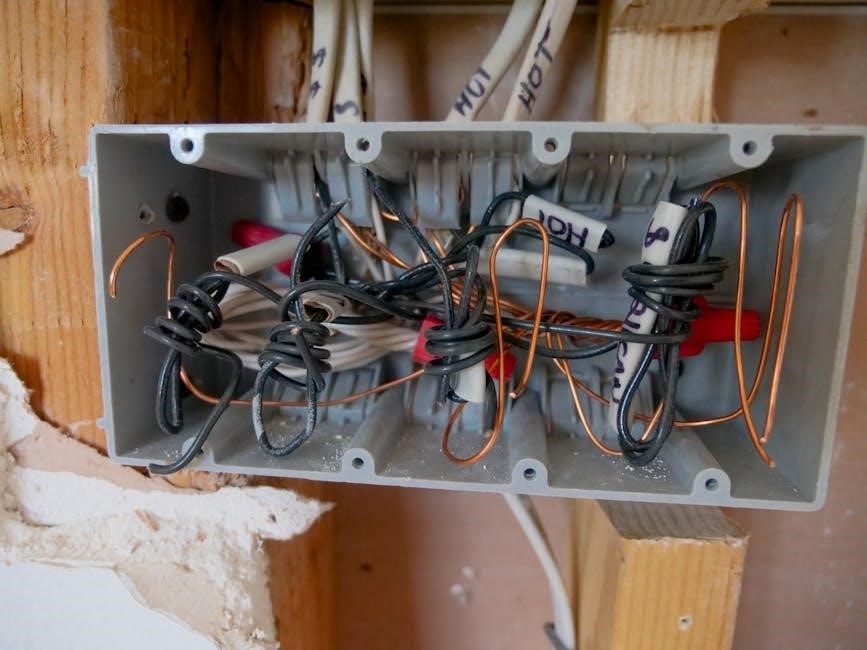

Tools and Materials Needed

Essential tools include drills‚ utility knives‚ measuring tapes‚ and fasteners. Additional materials like EPDM rubber washers‚ silicones‚ and sealing tapes ensure a secure and weatherproof installation.

Basic Hand Tools for Suntuf Installation

For Suntuf installation‚ essential hand tools include a utility knife or saw for cutting panels‚ a tape measure for accurate measurements‚ and a pencil for marking. A screwdriver or wrench is needed for tightening fasteners‚ while a rubber mallet can help tap panels into place without damage. Gloves and safety glasses protect against sharp edges and debris. Additionally‚ a ladder or step stool may be necessary for reaching elevated areas. These basic tools ensure a smooth and efficient installation process‚ allowing you to handle panels safely and securely.

Power Tools Required for the Job

Power tools are essential for efficiently installing Suntuf panels. A cordless drill or impact driver is necessary for pre-drilling holes and securing fasteners. A circular saw or jigsaw can be used to cut panels to size‚ while a grinder may help smooth cut edges. Additionally‚ a rotary tool can be useful for precise cuts or adjustments. Ensure all tools are equipped with appropriate blades or bits designed for polycarbonate materials to avoid damage. Using the right power tools ensures clean cuts and secure fastening‚ making the installation process faster and more professional. Always wear safety gear‚ such as gloves and goggles‚ when operating power tools.

Additional Materials for a Secure Installation

Besides the essential tools‚ several materials are crucial for a secure and weather-tight Suntuf installation. EPDM rubber washers are recommended to create a watertight seal around fasteners‚ preventing leaks. Silicone sealant and flashing tape are necessary for sealing gaps and ensuring weatherproofing‚ especially around edges and overlaps. Closure strips or end caps are used to seal the open sides of Suntuf panels‚ protecting them from debris and moisture. Additionally‚ H-channels or extruded aluminum profiles can be used for supporting panel ends and providing a clean finish. Always follow the manufacturer’s guidelines for compatible materials to ensure longevity and performance of your Suntuf installation.

Measuring and Calculating Suntuf Panels

Measure your structure’s width and divide by 760mm for the number of panels needed. Ensure accurate calculations to avoid material waste and achieve a seamless installation.

How to Measure Your Structure for Suntuf

Measuring your structure accurately is crucial for a successful Suntuf installation. Start by measuring the width of your structure using a tape measure. Record this measurement to determine how many panels you’ll need. Next‚ measure the length and slope of the roof or area where the panels will be installed. Consider any obstructions‚ such as rafters or beams‚ that may affect panel placement. For corrugated panels‚ ensure the measurement aligns with the panel’s corrugation direction. Double-check all measurements for accuracy to avoid material waste and ensure proper fitment. This step sets the foundation for a smooth and efficient installation process.

Calculating the Number of Panels Needed

To determine the number of Suntuf panels required‚ start by dividing the width of your structure by the panel’s coverage‚ typically 760mm for corrugated Suntuf panels. This will give the number of panels needed per row. Next‚ measure the length of the structure to calculate how many rows of panels are required. Add 10% to your total to account for cuts and waste. Ensure proper overlap between panels‚ usually 50mm‚ to maintain structural integrity and weatherproofing. Double-check your calculations to avoid underestimating or overestimating materials. Accurate panel calculation ensures a seamless installation process and minimizes potential gaps or material shortages.

Cutting Suntuf Panels

Cut Suntuf panels safely using a circular saw or utility knife. Wear safety glasses and ensure panels are securely held. Store panels in a shaded‚ cool area before cutting to prevent warping. Use approved tools and follow manufacturer guidelines for precise cuts. Avoid exposure to direct sunlight during cutting to maintain material stability. Proper cutting ensures smooth installation and prevents damage to the panels. Always pre-drill holes for fasteners to avoid cracking. Follow safety precautions to achieve professional results. Cutting Suntuf panels requires attention to detail and adherence to best practices for a successful project outcome. Proper techniques ensure durability and weather resistance. Store leftover panels properly to maintain their quality. Cutting correctly is essential for a secure and long-lasting installation. Use appropriate blades to prevent excessive heat buildup during cutting. Ensure panels are clean and dry before cutting to avoid contamination. Follow all safety guidelines to protect yourself and the material during the cutting process. Cutting Suntuf panels is a critical step that requires precision and care. Use the right tools and techniques to achieve clean‚ accurate cuts. Proper cutting ensures the panels fit seamlessly during installation. Always refer to the manufacturer’s instructions for specific cutting recommendations. Cutting Suntuf panels is a straightforward process when done correctly. Use safety equipment and follow guidelines to avoid accidents. Cutting Suntuf panels requires patience and attention to detail. Proper techniques ensure the panels remain intact and ready for installation. Cutting Suntuf panels is a key part of the installation process. Use the right tools and methods to achieve professional results. Cutting Suntuf panels requires careful planning and execution. Follow safety tips and best practices for a successful project. Cutting Suntuf panels is essential for a proper fit. Use the correct tools and techniques to ensure accurate cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires precision and care. Use the right tools and methods to achieve clean cuts. Cutting Suntuf panels is a simple process when done correctly. Follow safety tips and manufacturer recommendations for best results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and techniques to ensure accuracy and safety. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and methods for clean‚ precise cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for professional results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and techniques to achieve accurate cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires precision and care. Use the right tools and methods to ensure clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and techniques to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and methods to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and techniques for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and methods to achieve precise cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and techniques for clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and methods to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and techniques to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and methods for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and techniques to achieve precise cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and methods for clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and techniques to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and methods to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and techniques for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and methods to achieve precise cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and methods for clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and techniques to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and methods to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and techniques for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and methods to achieve precise cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and methods for clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and techniques to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and methods to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and techniques for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and methods to achieve precise cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and methods for clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and techniques to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and methods to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and techniques for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results. Cutting Suntuf panels requires careful planning and execution. Use the right tools and methods to achieve precise cuts. Cutting Suntuf panels is a straightforward process when done correctly. Follow safety tips and best practices for a successful project. Cutting Suntuf panels requires attention to detail and adherence to safety guidelines. Use the right tools and methods for clean cuts. Cutting Suntuf panels is a crucial step in the installation process. Follow all safety precautions and guidelines for optimal results. Cutting Suntuf panels requires careful attention to detail. Use the right tools and techniques to achieve professional results. Cutting Suntuf panels is a necessary step for a successful installation. Use appropriate tools and methods to ensure accuracy and safety. Cutting Suntuf panels requires precision and adherence to safety guidelines. Use the right tools and techniques for clean‚ accurate cuts. Cutting Suntuf panels is a critical part of the installation process. Follow safety precautions and manufacturer instructions for best results; Cutting Suntuf panels requires careful planning and execution. Use the right

Safety Precautions for Cutting Suntuf

Always wear safety glasses and gloves when cutting Suntuf panels to protect against debris. Use a dust mask in poorly ventilated areas to avoid inhaling particles. Ensure the cutting area is clear of clutter and tripping hazards. Avoid cutting in direct sunlight‚ as heat can cause warping. Use a saw with a fine-tooth blade to minimize dust and prevent overheating‚ which may release harmful fumes. Keep a fire extinguisher nearby as a precaution. Never cut Suntuf panels near open flames or sparks. Secure the panel firmly to prevent movement during cutting. Follow the manufacturer’s guidelines for safe cutting practices. Proper ventilation is essential when cutting indoors. Dispose of waste materials responsibly. Always store unused panels in a shaded‚ cool area to prevent damage. Cutting Suntuf panels requires attention to safety to avoid accidents and ensure a successful installation.

Best Practices for Cutting Suntuf Panels

For clean cuts‚ use a fine-tooth saw or a circular saw with a carbide-tipped blade. Score the panel with a utility knife and straightedge before sawing to ensure a straight line. Always cut on a flat‚ stable surface to maintain control. Use a clamp or vice to secure the panel‚ preventing movement during cutting. Apply gentle‚ consistent pressure to avoid overheating‚ which can warp the material. After cutting‚ smooth the edges with sandpaper or a file to remove sharp burrs. For curved cuts‚ use a jigsaw with a fine-tooth blade‚ but note that Suntuf panels are not designed for cold bending. Pre-drill holes for fasteners to prevent cracking. Use PALRAM-approved accessories for a secure and weather-tight installation. Proper cutting ensures a professional finish and extends the panel’s lifespan.

Installing Suntuf Panels

Begin by laying the first panel evenly‚ ensuring proper alignment with the structure. Secure subsequent panels tightly‚ aligning edges and seams for a seamless fit and weather-tight seal.

Laying the First Panel Correctly

Start by positioning the first Suntuf panel at the lowest edge of the structure‚ ensuring it is aligned with the frame. Secure it immediately with fasteners to maintain stability. Properly aligning the first panel is crucial as it sets the foundation for the rest of the installation. Use a level to ensure accuracy and prevent misalignment. Pre-drill holes to avoid cracking the material. Tighten fasteners firmly but avoid over-tightening‚ which may damage the panel. Ensure the panel lies flat‚ with no warping or bending. This step ensures a smooth and professional-looking finish for your project.

Aligning and Securing Subsequent Panels

After laying the first panel‚ align subsequent panels by ensuring they fit snugly into the H-channels or overlap correctly. Use a level to maintain proper alignment and prevent uneven installation. Secure each panel with fasteners‚ starting from the center and working outward to avoid warping. Ensure panels are spaced according to manufacturer guidelines to allow for thermal expansion. Use EPDM rubber washers to seal fasteners and prevent leaks. Double-check alignment as you progress to maintain a uniform appearance. Tighten fasteners firmly but avoid over-tightening‚ which can damage the panel or compromise its integrity. Proper alignment and securing ensure a durable and weather-tight installation.

Handling Horizontal and Vertical Seams

When installing Suntuf panels‚ handle horizontal and vertical seams with care to ensure a watertight seal. For horizontal seams‚ overlap panels by 10-15mm and secure with fasteners‚ aligning them properly to maintain structural integrity. Vertical seams should align with support beams to distribute weight evenly. Use H-channels or closure strips to cover vertical seams‚ ensuring they are tightly fitted; Apply silicone sealant along all seams for added weatherproofing. Proper handling of seams prevents leaks and enhances durability. Always follow manufacturer guidelines for seam placement and securing methods to achieve a professional finish and ensure long-lasting performance of your Suntuf installation.

Securing Suntuf Panels

Use approved fasteners with EPDM rubber washers to ensure a secure‚ weatherproof attachment. Pre-drill holes to avoid cracking and tighten evenly for a durable installation.

Choosing the Right Fasteners for Suntuf

Selecting the appropriate fasteners is crucial for a secure and weatherproof Suntuf installation. Use self-tapping screws with EPDM rubber washers to prevent water leaks and ensure a tight seal. Avoid using standard metal washers‚ as they may not provide adequate protection against moisture. Always pre-drill holes to avoid cracking the panels and apply even pressure while tightening. For optimal results‚ use fasteners specifically designed for polycarbonate panels‚ as they are built to withstand outdoor conditions. Refer to the manufacturer’s guidelines for recommended fastener types and spacing to ensure long-term durability and performance of your Suntuf panels.

- Use EPDM rubber washers for weatherproofing.

- Avoid standard metal washers.

- Pre-drill holes to prevent cracking.

Pre-Drilling Holes for Fasteners

Pre-drilling holes for fasteners is essential to ensure a smooth and damage-free installation of Suntuf panels. Use a drill bit slightly smaller than the fastener to guide it accurately. Drill through both the panel and the supporting structure‚ maintaining a consistent depth to avoid unevenness. For corrugated panels‚ align the drill bit with the crest of the corrugation to maximize strength. Apply steady pressure and work slowly to prevent cracking. After drilling‚ inspect the holes for any debris or rough edges. Properly aligned and cleanly drilled holes ensure secure fastening and prevent water infiltration. Always refer to the manufacturer’s guidelines for specific drilling recommendations to maintain the panel’s integrity and performance.

- Drill pilot holes slightly smaller than the fastener.

- Align with corrugation crests for strength.

- Inspect holes for debris or rough edges.

Securing Panels to the Structure

Securing Suntuf panels to the structure requires precision to ensure durability and weather resistance. Begin by attaching panels at the center‚ working outward to prevent warping. Use approved fasteners with EPDM rubber washers to create a watertight seal. Tighten screws evenly‚ avoiding overtightening‚ which can damage the panel or strip the fastener holes. Ensure panels are aligned with the structure’s frame‚ leaving no gaps for water infiltration. For corrugated panels‚ fasten through the crest of the corrugation for maximum strength. Double-check all connections to confirm they are secure and properly seated. This method ensures a stable and long-lasting installation‚ protecting your project from environmental stresses.

- Start fastening from the center to avoid warping.

- Use EPDM washers for a watertight seal.

- Align panels with the frame for a snug fit.

Sealing and Flashing

Proper sealing ensures weatherproofing‚ while flashing prevents water damage at intersections. Use EPDM rubber washers‚ silicone sealants‚ and approved tapes for a watertight finish‚ enhancing durability.

Importance of Proper Sealing

Proper sealing is essential to ensure the longevity and performance of Suntuf panels. It prevents water infiltration‚ reduces noise from rain‚ and minimizes dust and debris entering the structure. Without adequate sealing‚ panels may leak‚ leading to water damage and structural issues. Additionally‚ sealing protects the panels from extreme weather conditions‚ such as heavy rain or hail‚ ensuring they remain durable and maintain their aesthetic appeal. Using approved materials like EPDM rubber washers and silicone sealants is crucial for achieving a watertight seal. Proper sealing also enhances the overall energy efficiency of the structure by preventing air leaks. Always follow manufacturer guidelines to ensure a secure and long-lasting installation.

Applying Flashing for Weatherproofing

Applying flashing is a critical step in ensuring the weatherproofing of your Suntuf installation. Flashing helps seal gaps where panels meet walls‚ gutters‚ or other structures‚ preventing water infiltration. Use high-quality‚ waterproof flashing materials‚ such as silicone sealants or flashing tape‚ to cover edges and joints. Ensure the surface is clean and dry before applying flashing for optimal adhesion. Cut flashing material to size‚ leaving extra for overlapping at seams. Apply it along the entire length of panel edges and around fasteners to create a watertight seal. Properly applied flashing protects against rain‚ wind‚ and extreme weather conditions‚ ensuring your Suntuf panels remain durable and leak-free for years to come.

Maintenance and Care

Regularly clean Suntuf panels to maintain clarity and durability. Inspect for damage or loose fasteners and repair promptly to ensure long-lasting performance and weather resistance.

Cleaning Suntuf Panels

Regular cleaning is essential to maintain the clarity and durability of Suntuf panels. Use a mild detergent mixed with water and a soft cloth or sponge to wipe away dirt and debris. Avoid using abrasive materials or harsh chemicals‚ as they can scratch or damage the surface. For tougher stains‚ gently scrub with a non-abrasive brush before rinsing thoroughly with distilled water to prevent mineral spots. Cleaning should be done on a cool‚ shaded surface to avoid water spots from direct sunlight. This routine maintenance ensures optimal light transmission and extends the lifespan of your Suntuf panels‚ keeping them looking like new while maintaining their weather-resistant properties.

Inspecting and Repairing Panels

Regular inspection of Suntuf panels is crucial to ensure their durability and performance. Check for cracks‚ damaged fasteners‚ or signs of wear‚ especially around seams and joints. For minor damage‚ clean the area thoroughly before applying a compatible sealant. For larger cracks or holes‚ consider replacing the panel entirely. Ensure all fasteners are securely tightened but avoid over-tightening‚ which can cause warping. If water leakage is detected‚ inspect the flashing and sealing for gaps. Addressing issues promptly prevents further damage and maintains the structural integrity of your installation. Always follow the manufacturer’s guidelines for repairs to ensure longevity and warranty compliance.

Common Mistakes to Avoid

Common mistakes include over-tightening fasteners‚ which can warp panels‚ and improper alignment‚ leading to structural issues. Always follow installation guidelines carefully to ensure a secure and durable setup.

Over-Tightening Fasteners

Over-tightening fasteners is a common mistake that can damage Suntuf panels. Excessive pressure can warp the material or strip the screws‚ compromising the panel’s integrity. To avoid this‚ use a screwdriver instead of a drill for final tightening and ensure even pressure. Check each fastener for snugness without over-tightening. If a panel becomes warped‚ loosen the fasteners slightly and allow the material to relax before resecuring. Proper torque ensures a secure installation without risking panel damage. Always refer to the manufacturer’s guidelines for recommended tightening specifications to maintain the durability of your Suntuf panels and ensure a leak-free‚ stable structure.

Improper Alignment of Panels

Improper alignment of Suntuf panels is a common mistake that can lead to water pooling‚ structural weakness‚ and reduced panel lifespan. Panels must be aligned with the structure’s supports to ensure even weight distribution. Start by marking the area accurately and using a level to guide placement. Misaligned panels can cause uneven stress‚ leading to cracks or breaks. To avoid this‚ use alignment tools or spacers to maintain consistency. Always check the manufacturer’s guidelines for proper spacing and fit. Ensuring panels are straight and evenly spaced guarantees a secure‚ weather-tight installation. Proper alignment is crucial for the longevity and performance of Suntuf panels in any project.

Additional Tips and Tricks

Troubleshooting

Address common issues like leaks or warped panels by inspecting for loose fasteners‚ improper sealing‚ or uneven surfaces. Ensure panels are securely fastened and aligned properly.